CYB3000 series level transmitter

2021年1月8日

CYB4500 series wireless pressure transmitters

2021年1月12日1 Introduction

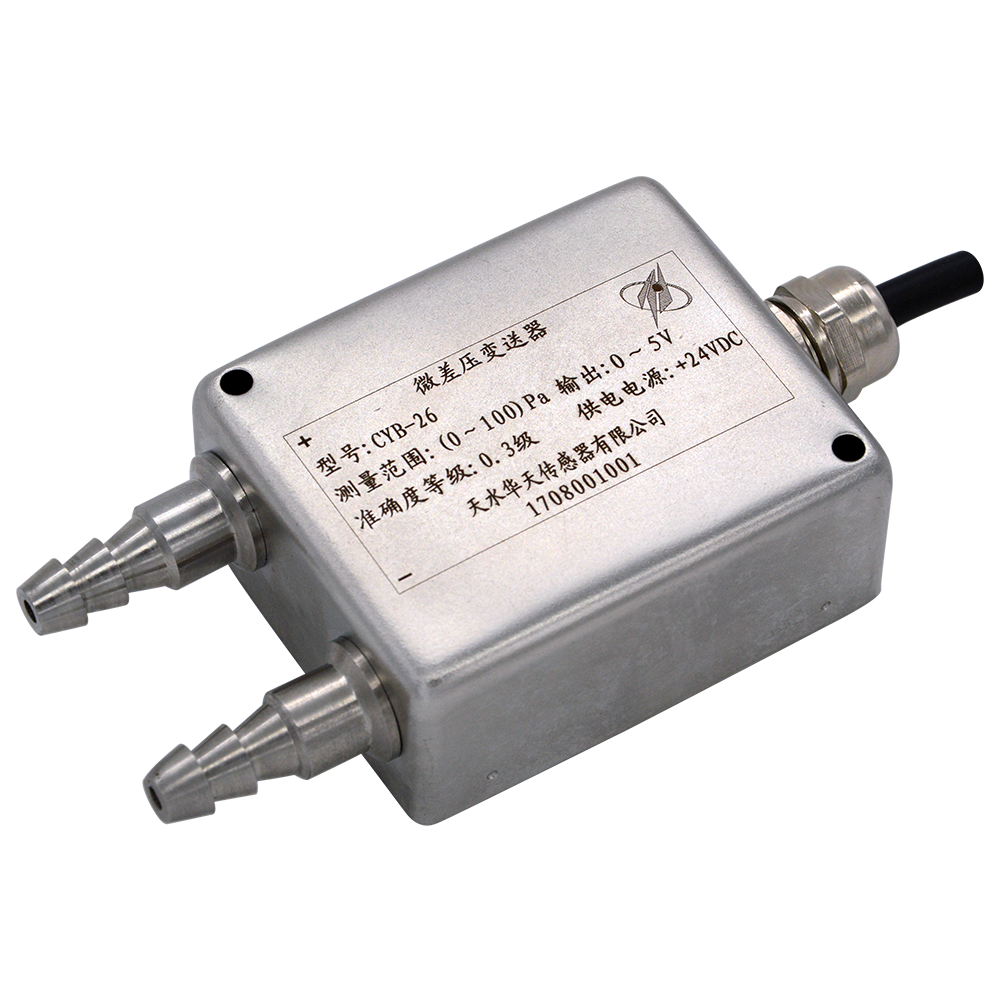

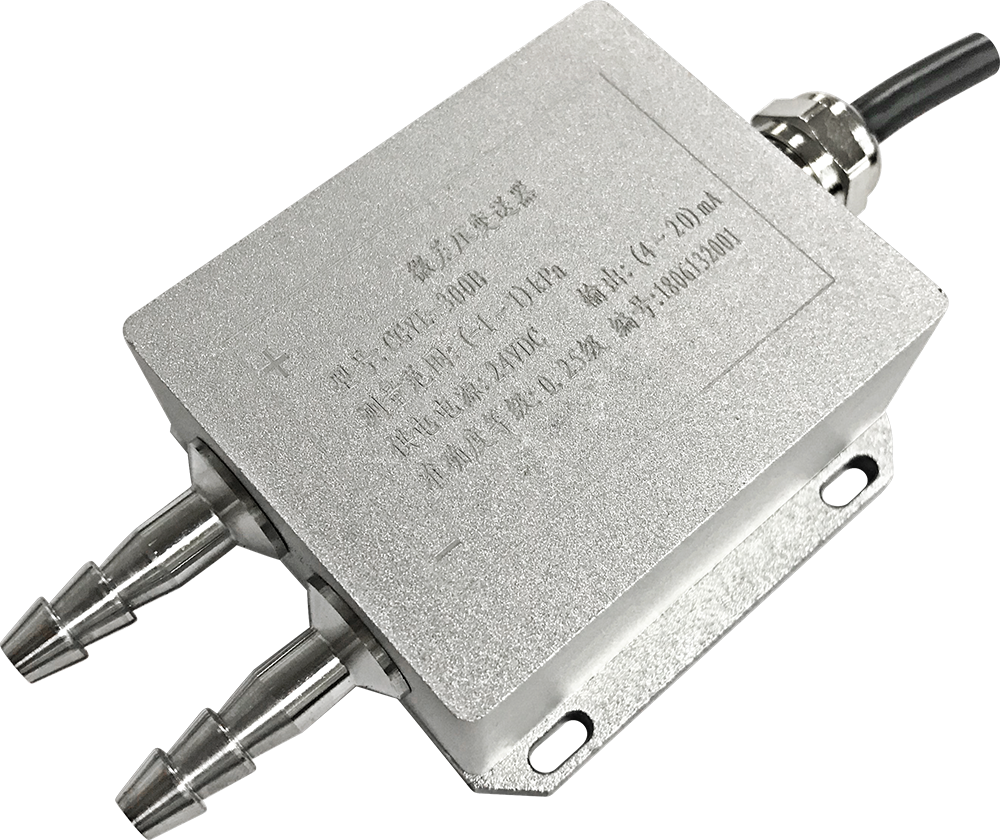

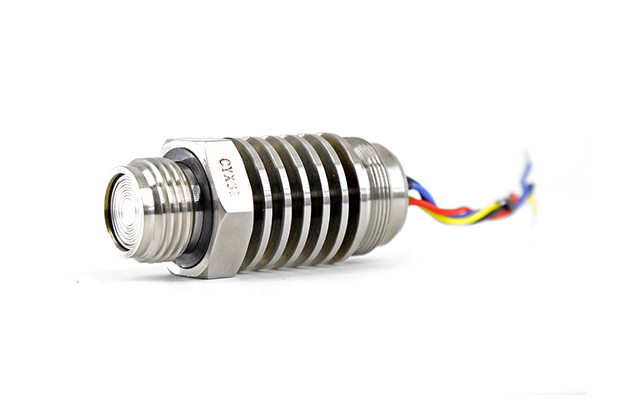

CYB2600 series micro differential pressure transmitter adopts silicon MEMS Micro Pressure chip. After temperature compensation, linear compensation, signal amplification, V / I conversion, surge, reverse polarity protection and other transmission circuit signal processing, CYB2600 series micro differential pressure transmitter outputs industrial standard 4-20mA signal. All digital calibration, no movable potentiometer, temperature drift performance, stability has been improved.

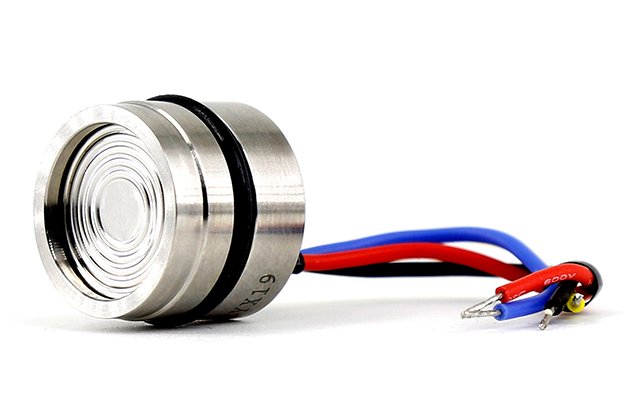

This series of products adopt two isolation methods. Less than 5kPa, the chip is protected by elastic silicon gel. It is mainly used for differential pressure measurement of non corrosive gases for silicon and silicon gel. The range of 5kPa and above is measured. The chip is protected by 316L stainless steel isolation diaphragm, and is filled with silicone oil. It is suitable for medium measurement of stainless steel without corrosion.

2 Features

This series of transmitters are used in petroleum, chemical, metallurgy, electric power, textile, electronics, medicine, food, environmental protection and other fields, and more widely used in HVAC, purification plant and boiler automatic detection.

3 Technical indicators

|

Range |

Pa |

0~±100、500……1000 |

||

|

KPa |

0、2、10……100 |

|||

|

Form of pressure |

Differential pressure |

|||

|

Output signal (mA) |

4~20 |

|||

|

0~ 5V (0 ~ 10) three wire system |

||||

|

Accuracy level |

0.25 |

0.5 |

1.0 |

|

|

Nonlinear(FS%) |

≤0.2 |

≤0.4 |

≤0.8 |

|

|

Hysteresis, repeatability(FS%) |

≤0.05 |

≤0.1 |

≤0.2 |

|

|

Zero and sensitivity temperature drift (%FS/℃) |

≤0.025 |

≤0.05 |

≤0.08 |

|

|

Long term stability(%FS/year) |

≤0.2 |

≤0.5 |

≤1.0 |

|

|

Operating voltage(VDC) |

+12~+36 (calibration value is + 24) |

|||

|

Compensation temperature (℃) |

0~+50 |

|||

|

Operating temperature (℃) |

-40~+85 |

|||

|

Overload capacity (%) |

200 |

|||

|

Static pressure(kPa) |

≤200 |

|||

|

Load resistance(Ω) |

R=(U-12.5)/0.02-RD Where: u is the power supply voltage and RD is the internal resistance of the cable |

|||

|

Response time (10% – 90%) ms |

≤1 |

|||

|

Measuring medium |

<5kPa,Non corrosive gas. ≥5kPa,Compatible with 316L and silicon. |

|||

|

Diaphragm material |

Silicon gel /316L membrane |

|||

|

Shell material |

304、LY12 |

|||

|

Interface |

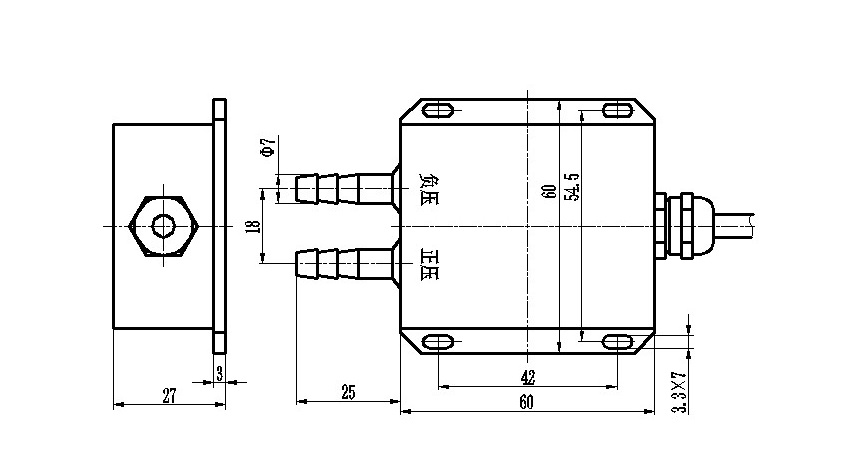

304 stainless steel Φ 7 tower nozzle |

|||

|

Protection level |

IP66 |

|||

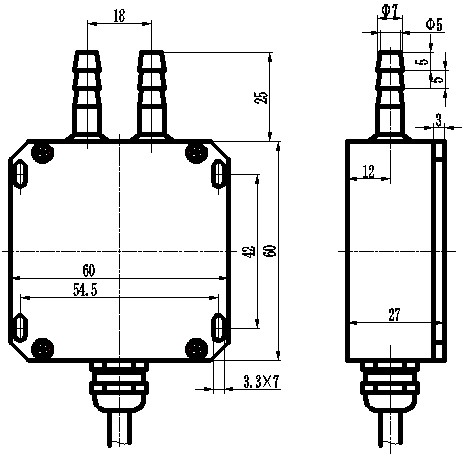

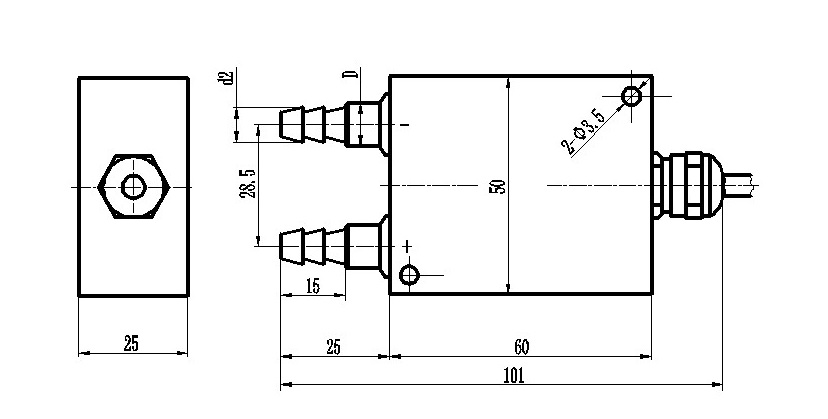

4 Transmitter size

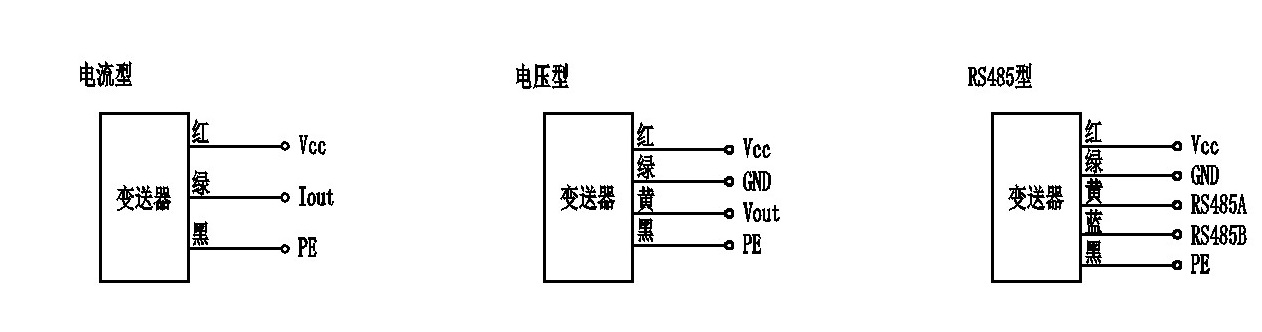

5 Electrical connection

6 Selection Guide

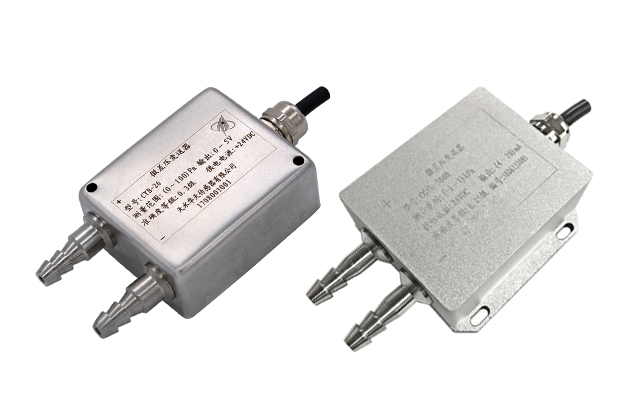

6.1 Model and shape

|

Model |

Features |

Pattern |

|

CYB2612 |

Stainless steel square shell;Tower type nozzle, back need thread can be customized; Pressure interface materials 304 and 316L are optional; 316L isolation diaphragm core can be selected for measuring range above 5kpa. |

|

|

CYB2613 |

Aluminum alloy square shell; 304 stainless steel nozzle of Ф 7 tower type; 316L isolation diaphragm core can be selected for measuring range above 5kpa. |

|

6.2 Selection Guide

|

CYB2600 |

Differential pressure transmitter |

||||||||

|

|

range |

measuring range±100Pa…100kPa |

|||||||

|

10n |

In PA, the first two digits are multiplied by the n-square of 10, and N is the third digit value. |

||||||||

|

|

|

Code name |

Form of pressure |

||||||

|

D |

Differential pressure type |

||||||||

|

|

|

Code name |

Supply voltage |

||||||

|

U1 |

24VDC |

||||||||

|

U2 |

12VDC |

||||||||

|

U3 |

5VDC |

||||||||

|

U4 |

3VDC(3.3VDC) |

||||||||

|

U5 |

Other power supply modes |

||||||||

|

|

|

Code |

output signal |

||||||

|

E1 |

4mA~20mADC |

||||||||

|

E2 |

0mA~10mADC |

||||||||

|

E3 |

0mA~20mADC |

||||||||

|

V1 |

1VDC~5VDC |

||||||||

|

V2 |

0VDC~5VDC |

||||||||

|

V3 |

0VDC~10VDC |

||||||||

|

V4 |

0.5VDC~4.5VDC |

||||||||

|

V5 |

Other voltage output |

||||||||

|

R4 |

RS485 communication interface |

||||||||

|

Ⅱ |

I2C Protocol communication |

||||||||

|

CYB2613 [102] D U1 E1 Indication: cyb2613 type 1kPa differential pressure power supply, 4 ~ 20mA output。 |

|||||||||

7 Precautions

7.1 When receiving the product, please check whether the package is in good condition, and check whether the transmitter model and specification are consistent with the product you purchased.

7.2 Please keep the verification certificate and certificate, and return it with the product during maintenance.

7.3 Pay attention to the installation direction of the transmitter. Generally, the transmitter should be horizontally debugged and installed horizontally; the vertical installation should be explained when ordering or adjusting the zero point of the secondary instrument.

7.4 The transmitter shall not be installed in the environment of mechanical vibration and strong electromagnetic interference.

7.5 In low temperature environment, in order to ensure the accurate measurement of pressure, it is necessary to ensure the fluidity of the measured medium.

7.6 The transmitter is a precision instrument and should be stored in a dry and ventilated indoor environment to avoid direct sunlight.